NPT-01 Needle Puncture Tester

- Download Catalog

What is Syringe Needle Penetration Test?

Needle Penetration Test, also called needle puncture test, simulates the insertion of needle-like objects into materials such as rubber, closure, protective material, skin, film, etc., to assess their resilience and reaction. This procedure is essential for guaranteeing material integrity and safety, particularly for items requiring proper puncture resistance.

The Needle Penetration Test serves a vital function in ensuring the safety, dependability, and efficacy of various products, including hypodermic needles, synthetic skin, rubber stoppers, protective gloves, garments, medical closures, and infusion bag films.

Therefore, choosing a reliable needle puncture tester, or penetration tester is essential for ensuring product quality and safety.

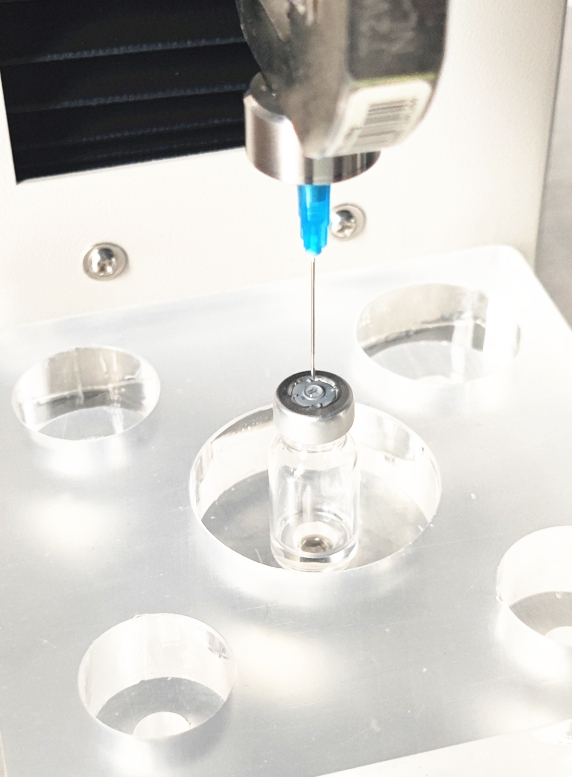

Syringe Needle Penetration Test Jig

The Needle Penetration Test Jig includes the needle connector to the loadcell and the vial bottle holder, specially made according to the vial diameter, so the rubber stopper center is always beneath the needle point.

How is NPT-01 Needle Puncture Tester helping?

NPT-01 Needle Puncture Tester is developed by Cell Instruments for professionals in various industries that require penetration/puncture testing. It can come equipped with various types of needles and a variety of sample-holding fixtures.

Understanding Needle Penetration Testing Procedure

In this process, a selected needle is linked to a load cell, while a particular substrate or sample is positioned on a stable support atop the tester’s base. The needle then advances at a consistent velocity until it penetrates the material sample. Subsequently, the force applied during the puncture is measured as the puncture force.

Technical Features and Benefits

1. Includes a PLC control system and a 7-inch HMI touch screen interface. Ease of operation and user-friendly.

2. Utilizes precise ball screw and stepper motor technologies to ensure reliable and precise testing speed.

3. Flexible test speed range gives versatile testing options

4. Provides a range of sample fixtures and needle variations in diameter and tip. Increases its adaptability.

5. Safety measures like position limiters and overload protection.

6. Automatic return function after testing. Improved efficiency

7. A dot matrix micro printer for extended data retention. Long-term data preservation

Specifications

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~300mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Standards in Needle Penetration/Puncture Test

ISO 7864, GB 15811, GB/T 10004,ASTM F2878,ASTM F1342,EN 388,YY/T0616.4,YBB 00112005, YBB 00242004,YBB 00322004,YBB 00342002,YBB 00102005

Q&A

N/A

Configuration

Main machine, softgel holder, probe, microprinter, loadcell

Software, customized probe, loadcell, etc

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.