Break Loose and Glide Force Testing Method

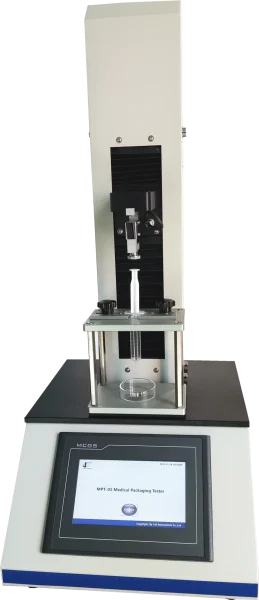

The Break Loose and Glide Force Testing Machine is an advanced testing device designed for the mechanical verification of syringes, particularly focusing on testing the forces required to operate the plunger. These tests, known as syringe break loose and syringe glide force testing, are critical in ensuring that syringes perform consistently and safely when used for medical injections.

Break Loose and Glide Force Testing

What is Syringe Break Loose Force Testing?

The syringe break loose force refers to the initial force required to move the syringe plunger from its resting position. This force must be neither too high, which could make the syringe difficult for the user to operate, nor too low, which could lead to leakage or failure to inject the fluid properly. Accurate measurement of this force is crucial for ensuring safe and effective syringe use.

What is Syringe Glide Force Testing?

The syringe glide force is the continuous force needed to move the plunger once it has been broken loose. It reflects the friction and resistance the plunger encounters as it moves through the syringe barrel. This measurement ensures that the plunger slides smoothly and without obstruction, which is essential for delivering the correct dosage of fluid.

Both of these force measurements are integral to ensuring that syringes work as intended under real-world conditions. These tests also help manufacturers meet safety standards and improve the overall user experience.

Key Standards for Syringe Glide Force Testing

The Break Loose and Glide Force Testing Machine is designed to meet the stringent requirements of several internationally recognized standards. These standards ensure that the syringes are tested under consistent conditions and their performance aligns with global best practices.

- USP 382: Standard for Syringe Testing The USP 382 standard provides comprehensive guidelines for testing syringes, especially in terms of mechanical integrity.

- ISO 7886-1: Syringes for Medical Use – Part 1 ISO 7886-1 outlines the design, performance, and testing requirements for disposable syringes.

- ISO 8537: Pre-filled Syringes ISO 8537 focuses on pre-filled syringes and specifies the testing methods for determining the syringe glide force and break loose force.

- ISO 11040-4: Syringe Design and Performance The ISO 11040-4 standard deals with the design and performance of syringes, including testing the forces required to operate the plunger.

- ISO 11608-5: Needle-Based Injection Systems ISO 11608-5 provides guidelines for testing needle-based injection systems, focusing on the operational forces of these devices.

Why Choose Cell Instruments' Break Loose and Glide Force Testing Machine?

Testing Program Features The Break Loose and Glide Force Testing Machine is equipped with multiple test programs to assess various force-related parameters:

- Break Loose Force Testing: Measures the force required to initiate plunger movement.

- Glide Force Testing: Determines the force necessary to continue moving the plunger once it has been broken loose.

- Plunger Pull-out Testing: Verifies the integrity of the plunger’s design under stress.

This multi-functionality allows manufacturers to ensure that their syringes meet the specific standards of USP 382, ISO 7886-1, ISO 8537, ISO 11040-4, and ISO 11608-5.

- Reliable and Trusted: Manufactured to meet the highest standards in the industry, ensuring reliable and repeatable test results.

- Versatile and Comprehensive: This machine is suitable for a wide range of testing applications, including syringes, pre-filled syringes, and other medical devices.

- User-Friendly: Designed with ease of use in mind, offering intuitive controls and automated functions to enhance productivity.

- Cost-Effective and Powerful: This machine combines multiple testing programs into one unit, saving both time and money for manufacturers.

- Versatility for Medical Material Testing: In addition to syringes, the machine can be used for testing a range of other medical materials and packaging components.

- Automated Test Process: The system is designed for easy operation, with automated processes that reduce the need for manual intervention and increase testing efficiency.

ISO 9626

System Suitability Testing Pharmacopoeia for Glass Ampoules

Package Compression Test

Sodium Chloride Ampoule Force Testing Guide for ISO 9187-1 Compliance