The Vacuum Leak Tester for Syringe Plunger Stopper and Seal is an essential tool for assessing the airtightness of syringes. This testing method follows ISO 7886-1, particularly Annex B, which outlines procedures for detecting air leakage and plunger stopper separation.

ISO 7886-1 Leak Testing Procedure

ISO 7886-1 specifies the requirements for sterile hypodermic syringes intended for single use. Annex B provides a standardized method to evaluate air leakage past the plunger stopper and the potential detachment of the plunger stopper from the plunger.

Test Method Overview

The test method involves partially filling the syringe with distilled water and applying a negative pressure through the nozzle while the plunger is clamped in place. Observing for air leakage or plunger stopper detachment ensures that the syringe maintains a proper seal.

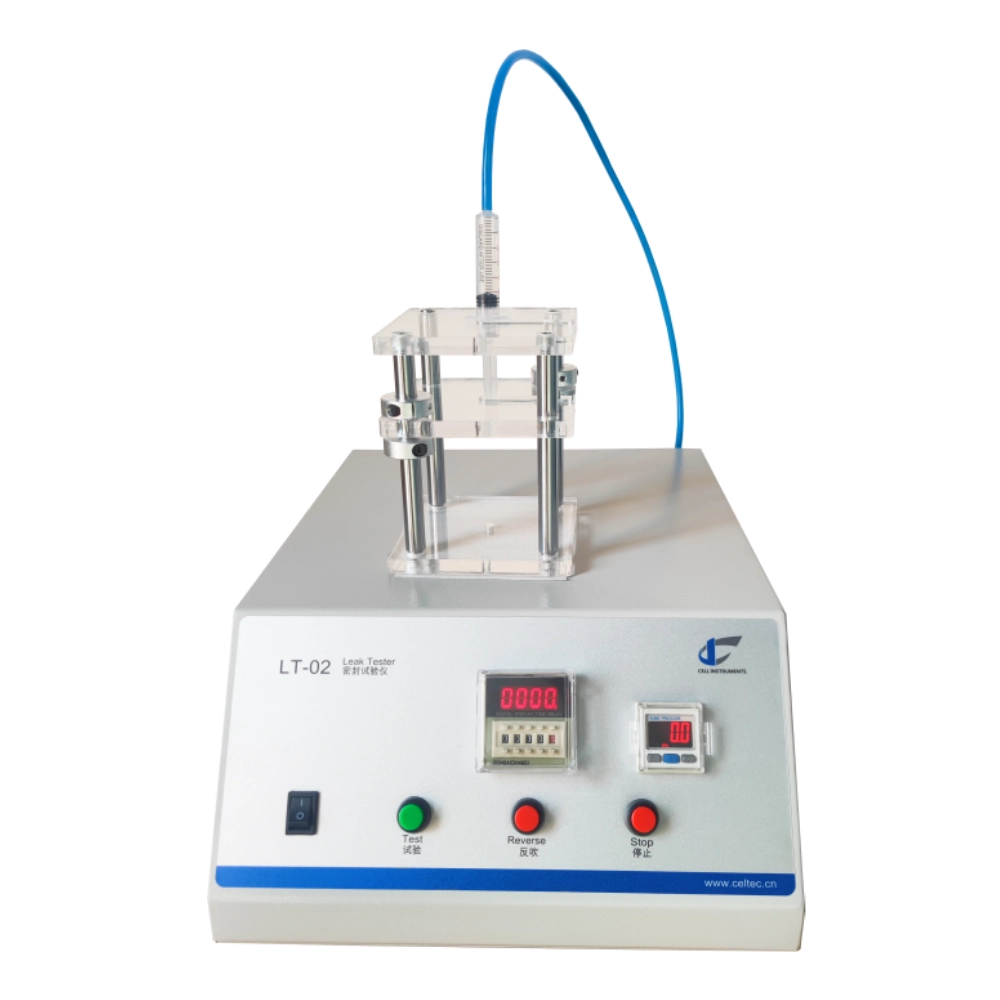

Key Apparatus for Testing

Tubing set with compatible conical fitting (ISO 80369-7 compliant)

Support and clamping device for holding the syringe plunger

Vacuum generator, manometer, and vacuum-tight valve system

Distilled water (18°C to 28°C)

How the Vacuum Leak Tester Works

The Vacuum Leak Tester for Syringe Plunger Stopper and Seal operates through a controlled vacuum process:

Fill the syringe with at least 25% of its nominal capacity using distilled water.

Clamp the plunger stopper in a fixed position.

Connect the syringe nozzle to the conical fitting.

Generate a vacuum and gradually reduce pressure to 88 kPa below ambient atmospheric pressure.

Observe for air leakage or plunger stopper detachment.

Maintain vacuum isolation for 60 seconds, monitoring the manometer for pressure changes.

Record findings, including air leakage evidence, pressure variations, and stopper stability.

Choosing the Right Vacuum Leak Tester for Compliance

Selecting a reliable ISO 7886-1 leak tester requires:

High vacuum control precision to detect minor leaks

Compliance with ISO 7886-1

User-friendly interface for ease of operation

Reliable data recording system for traceability

Main Parameter

| Test Range | 0~-90KPa |

| Air Input | 0.6~0.7 Mpa |

| Test Time | 9999H |

| Power | 220V |

Why Use a Vacuum Leak Tester for Syringe Plunger Stopper and Seal?

Ensures compliance with ISO 7886-1 and Annex B

Detects potential risks of contamination due to leakage

Verifies the mechanical integrity of syringes

Prevents product failures in pharmaceutical applications

Enhances quality control and regulatory compliance

The Vacuum Leak Tester for Syringe Plunger Stopper and Seal is a vital instrument for ensuring syringe integrity and compliance with ISO 7886-1 Annex B. By using this tester, manufacturers can enhance syringe reliability, minimize failure risks, and uphold the highest safety standards in medical applications.