Rupture Test For Soft Gelatin Capsules

The importance of rupture test for soft gelatin capsules in ensuring product quality and consumer safety cannot be overstated. This article describes ten crucial aspects of the compressive testing process for soft capsules, encompassing the selection of testing equipment, testing efficiency, testing speed, testing items, and the choice of measuring head diameter, among others.

By adhering to these key points, we can ensure the accuracy and reliability of the test results, ultimately delivering safe and effective products to consumers. Furthermore, through scientific analysis of the test data, we gain a deeper understanding of the capsules’ performance, enabling us to refine product designs and manufacturing processes accordingly.

Soft Gelatin Capsules Rupture Test Ensures Quality and Safety

Soft gelatin capsules play a crucial role in pharmaceutical manufacturing, where ensuring product quality is paramount. Among the essential processes is the rupture test for soft gelatin capsules, an indispensable step aimed at evaluating the capsules’ integrity under external pressure to prevent accidental ruptures during usage.

Capsule Hardness Test: Assessing Quality Parameters

In addition to the rupture test, the capsule hardness test is equally vital in assessing the quality of soft gelatin capsules. By measuring the capsules’ hardness, we gain insights into their compressive strength under external forces, thereby determining compliance with production standards.

Softgel Hardness Test and Rupture Test: Complementary Assessments

While the softgel hardness test focuses on the overall structural strength and stability of soft gelatin capsules, the rupture test emphasizes the capsules’ shell’s pressure resistance and toughness. Together, they form a comprehensive assessment system for evaluating soft gelatin capsule quality.

From Rupture to Compression: Comprehensive Testing

Beyond rupture tests and capsule hardness tests, assessments such as softgel rupture, capsule rupture, and capsule compression provide valuable data to understand the performance of soft gelatin capsules under different conditions, aiding in product optimization.

Safety and Protection Measures

– Ensure the safety of operators during testing to prevent accidents.

What we offer:

- The force overload auto stop to protect the loadcell.

- Tester beam overtravel protection to provent clash and potential hurt.

– Adhere to relevant safety regulations and operating procedures to maintain the normal operation and upkeep of testing equipment.

Testing Efficiency

– Choose equipment capable of completing tests quickly to reduce testing time and costs.

– Optimize testing procedures to minimize unnecessary operations and enhance efficiency.

– For testing large sample sizes, consider using automated or semi-automated testing equipment.

What we offer:

- Adjustable test speed.

- Test position UP and DOWN adjustment before a test to reduce the waiting waiting.

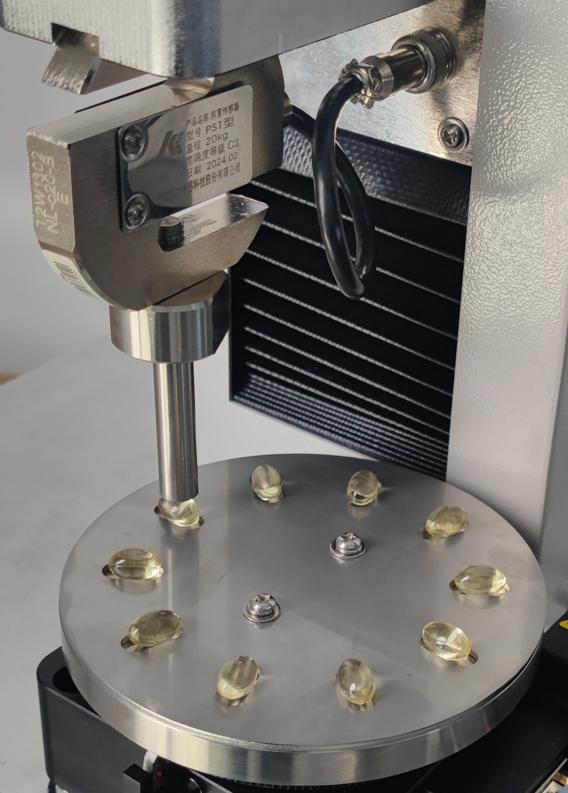

- Automatic sample feeding system equipped, with 10 samples installed at the same time.

- Sample holding plate interchangable and quick replacement.

Equipment Selection

The Continuous Softgel Feeding System

A ten sample positioning plate of auto rotating design to improve test efficiency and save labor

– Choose testing equipment with high precision and stability, such as soft gelatin capsule compression testers or universal material testing machines.

– Ensure equipment can simulate the pressure soft gelatin capsules may encounter during actual usage.

– Equipment should have data acquisition and recording capabilities for subsequent data analysis and report generation.

What we offer:

- Precious ball lead screw and stepper motor driving system, displacement accuracy is guaranteed.

- Different ways of testing programs to have total analysis of softgel, such as rupture force, deformation under compression, constance load.

- The data collected is auto listed and can be exported by dot matrix type micro printer.

- Softgel size suitable holding plate in stainless steel #316.

Testing Parameters

– Determine testing parameters, including compressive strength, deformation, rupture points, and other critical indicators.

– Depending on the type and intended use of soft gelatin capsules, additional specific testing parameters may be added.

– Ensure testing parameters comprehensively assess the compressive performance of soft gelatin capsules.

Selection of Measuring Head Diameter

– Select an appropriate measuring head diameter based on the size and shape of soft gelatin capsules.

– The measuring head diameter should accurately apply force to the surface of soft gelatin capsules, avoiding excessive or insufficient localized pressure.

– Different diameters of measuring heads may be required for different testing stages or types of soft gelatin capsules.

What we offer:

- Cylinder probes in 10mm diameter or in 10mm² surface.

- Other shape or diameter probes can be customized.

Rupture Test Probe for Soft Gelatin Capsules

Rupture tests and hardness tests are vital in soft gelatin capsule production. Through these tests, we can ensure the quality of soft gelatin capsules meets standards, providing consumers with safe and reliable products. Therefore, it is crucial to prioritize these testing processes continually, enhancing testing techniques and capabilities to contribute to the healthy development of the soft gelatin capsule industry.