Softgel Capsule Hardness Tester Application

A softgel is a specialized capsule used for oral medication, containing a liquid fill within a gelatin shell. It is commonly used for vitamins, minerals, and other drugs. The active ingredients are safely enclosed within the capsule, protecting them from the environment. When the consumer takes the capsule, the ingredients are released through crush, dissolution, melting, depending on the capsule wall’s strength.

The CHT-01 Capsule and Softgel Hardness Tester quantifies the softgel’s elasticity by measuring wall deformation under a specific compressive load. Seal strength is evaluated using a probe larger than the capsule, measuring the force required to break the seal. Additionally, the tester measures the force needed to deform the softgel to a specific level.

Benefits of Softgel Capsule Hardness Tester

- Multi Test programs realize comprehensive analysis of capsule in force, displacement and fixed load tetss

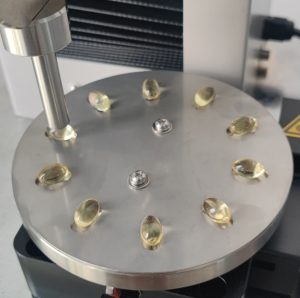

- Automatic Rotating softgel capsule sample table increases test efficiency

- Automatic statics saves operator’s valuable data dealing time

- Long and durable service life with its industrial level design and componets

- More extended applications avaiable for other types of samples and industries. For example, it can be seamliess switched to tablet hardness test and gelatin test; compression and hardness tests for laundry detergent pacs;paintball compression test; tests for play dough;physical analysis of cosmetic product such as lipstick, cream, lotion, toothpaste, etc.

Technical Features

- PLC control unit equipped and 7-inch HMI touch screen

- Precision ball screw and stepper motor used

- Variable test speed.

- Multiple fixtures customization available

- Position restrictor and overload protections

- Automatic returning function after test

- Dot matrix type microprinter

High Efficiency

The high efficiency feature of CHT-01 Capsule and Softgel Hardness Tester can not be overphasized.

The probe compresses each softgel with the rotation of sample table without human interfere. After all softgels are compressed, the system gives statistic results directly. One time sample placing of ten samples saves labor and waiting time too.

Technical Features

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~300mm/min (or as required) |

| Probe | SSφ10mm or 10mm² (Or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Micro printer, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Standards

The Softgel Capsule Hardness Tester complies with multi ASTM and ISO standards regarding the compression and hardness test of materials. The tester features a rotating sample feeding mechanism to realize ten sample readiness.

Q&A

The purpose of softgel compression testing is to evaluate the compressive strength of softgels under external forces, ensuring their stability and safety during actual use.

The Capsule and Softgel Hardness Tester is a specialized device used to test the compressive strength of softgels by simulating the pressures they may encounter during actual use.

Softgels may be subjected to external pressures during manufacturing, packaging, and transportation. Compression testing ensures that they are not easily ruptured or deformed thereby, maintaining the effectiveness of drug release and absorption.

Choosing the right Capsule and Softgel Hardness Tester involves considering factors such as its precision, stability, reliability, and ease of operation to ensure accurate assessment of the compressive strength of softgels. For professionals, Cell Instruments CHT-01 is an indeal choice.

Configuration

Main machine, softgel holder, probe, microprinter, loadcell

Software, customized probe, loadcell, etc