Ten Key Tests on intravenous bag Physical and Mechanical Performance

Intravenous bags, commonly referred to as IV bags or infusion bags, are indispensable in clinical settings, serving as vital containers for various medical fluids such as saline solutions and medications. Ensuring the quality and reliability of these bags is important to the safety and well-being of patients. This article delves into the intricate realm of physical and mechanical performance testing for intravenous bags, unveiling ten key tests essential for evaluating their durability and effectiveness

A. Tensile Strength and Elongation

Tensile strength and elongation are fundamental metrics that assess the resilience of intravenous bag materials under stress. Tensile strength measures the maximum stress a material can withstand before breaking, while elongation denotes its ability to stretch without fracturing. These properties are critical for preventing ruptures or leaks during handling and transportation.

Recommended Equipment: Cell Instruments Model TST-01 Tensile Tester.

B. Heat Sealing Strength

Heat sealing strength evaluation is crucial for assessing the integrity of the seals in intravenous bags. This test determines the effectiveness of heat-sealed areas in preventing leakage and contamination. A robust heat sealing strength ensures the hermetic closure of the bags, safeguarding the sterility of their contents.

Recommended Equipment: Cell Instruments Model HST-01 Heat Seal Tester.

C. Puncture Resistance and Puncture Retainer Tests

Puncture resistance testing measures the ability of intravenous bag materials to withstand puncture forces. Additionally, the puncture retainer test evaluates the bag’s capacity to retain the puncture device after being pierced. These tests are vital for ensuring the durability and reliability of intravenous bags during clinical use.

Recommended Equipment: Cell Instruments Model MPT-01 Medical Package Tester.

D. Puncture Site Impermeability and Injection Point Sealing Tests

The puncture site impermeability test examines the sealing integrity of injection points on intravenous bags post-puncture. Ensuring the hermetic closure of these sites is essential for preventing fluid leakage and maintaining the sterility of the contents.

E. Hanging Strength Test

The hanging strength test assesses the ability of intravenous bags to withstand the weight of their contents when hung for intravenous administration. Evaluating hanging strength is crucial for preventing accidental ruptures or failures during infusion procedures.

F. Opening Force Test for Aluminum-Plastic Combination Caps

This test determines the force required to open the aluminum-plastic combination caps commonly used in intravenous bag closures. Assessing the opening force ensures ease of access to the bag’s contents while maintaining the integrity of the seal.

Recommended Equipment: Cell Instruments Model MPT-01 Medical Package Tester.

G. Impact Resistance

Impact resistance testing evaluates the ability of intravenous bag materials to withstand impact forces during transportation and handling. Robust impact resistance is essential for preventing damage to the bags and ensuring the safety of their contents.

Recommended Equipment: Cell Instruments FDT-01 Dart Impact Tester

H. Tear Resistance

Tear resistance testing measures the ability of intravenous bag materials to resist tearing or propagation of existing tears. High tear resistance is critical for maintaining the structural integrity of the bags and preventing leaks or ruptures.

Recommended Equipment: Cell Instruments Model SLD-01 Tear Tester

I. Pressure Resistance

Pressure resistance testing simulates the stacking and compression forces experienced by intravenous bags during storage and transportation. Evaluating pressure resistance helps ensure that the bags can withstand external pressures without compromising their integrity.

Recommended Equipment: Cell Instruments Model LSST-01 Leak and Seal Strength Tester

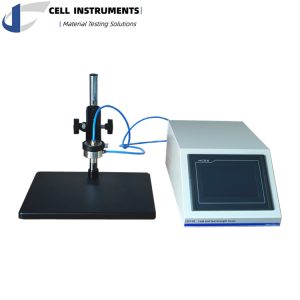

IV. Thickness Testing

Uniform thickness across intravenous bag materials is essential for maintaining consistent performance and barrier properties. Thickness testing ensures quality control and helps identify any deviations that may affect the bags’ durability or functionality.

Recommended Equipment: Cell Instruments Model FTT-01 Thickness Tester.

Mastering the physical and mechanical performance of intravenous bags through comprehensive testing is indispensable for ensuring the safety and efficacy of medical treatments. By adhering to stringent testing protocols and utilizing advanced equipment, manufacturers can uphold the highest standards of quality and reliability in intravenous bag production.

Table of Contents

Frequently Asked Questions

Puncture resistance testing ensures that intravenous bags can withstand piercing forces, preventing leaks and maintaining the integrity of the bag’s contents during clinical use.

Tear resistance testing assesses the bag’s ability to resist tearing, ensuring structural integrity and minimizing the risk of leaks or ruptures during handling and administration.

Pressure resistance testing evaluates the bag’s ability to withstand external pressures, such as stacking and compression forces, during storage and transportation, ensuring its durability and integrity.

Heat sealing strength testing assesses the effectiveness of seals in preventing leakage and contamination, crucial for maintaining the sterility of the bag’s contents and ensuring patient safety.

Hanging strength testing evaluates the bag’s ability to support its contents during intravenous administration, preventing accidental ruptures or failures that could compromise patient safety.