The Importance of Ampoule Breaking Force Testing

Ampoules, also known as ampuls, are suitable packaging materials for storing pharmaceutical products until they are administered to the patient. The force needed to break them cleanly can greatly impact patient safety and treatment outcomes.

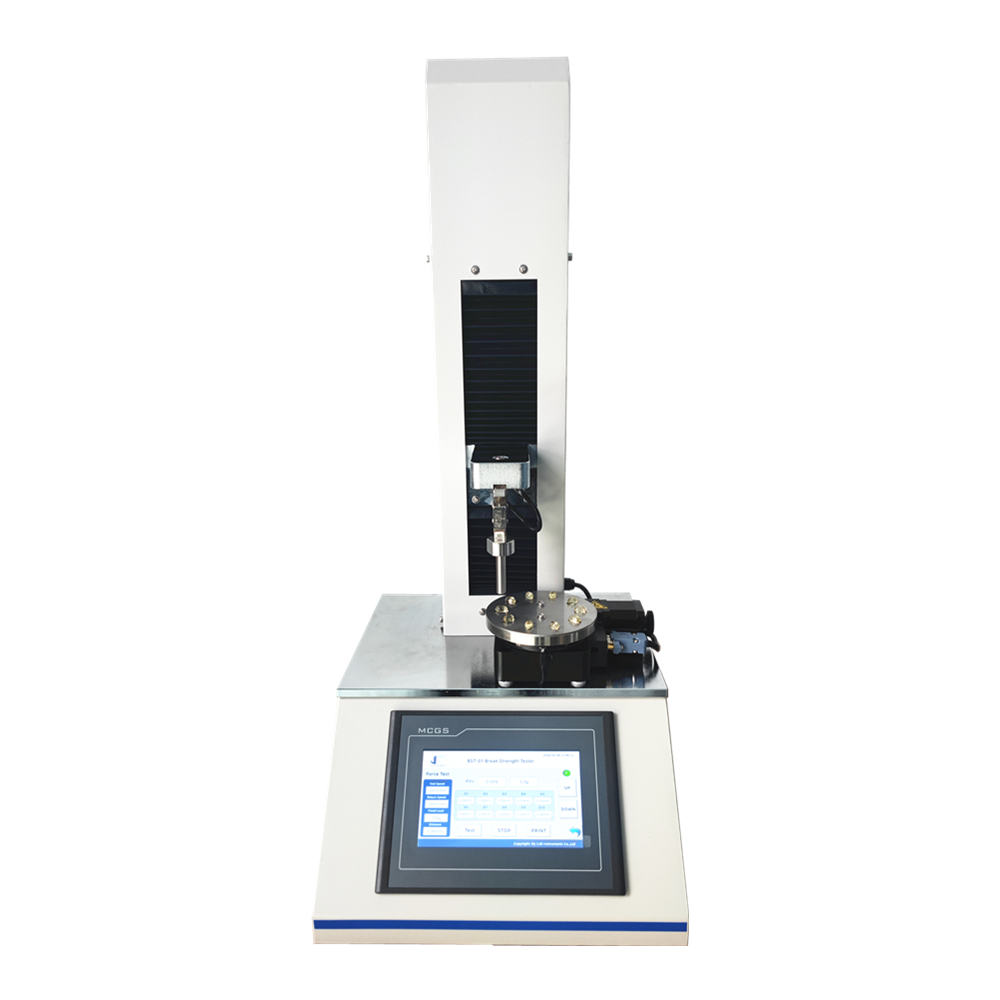

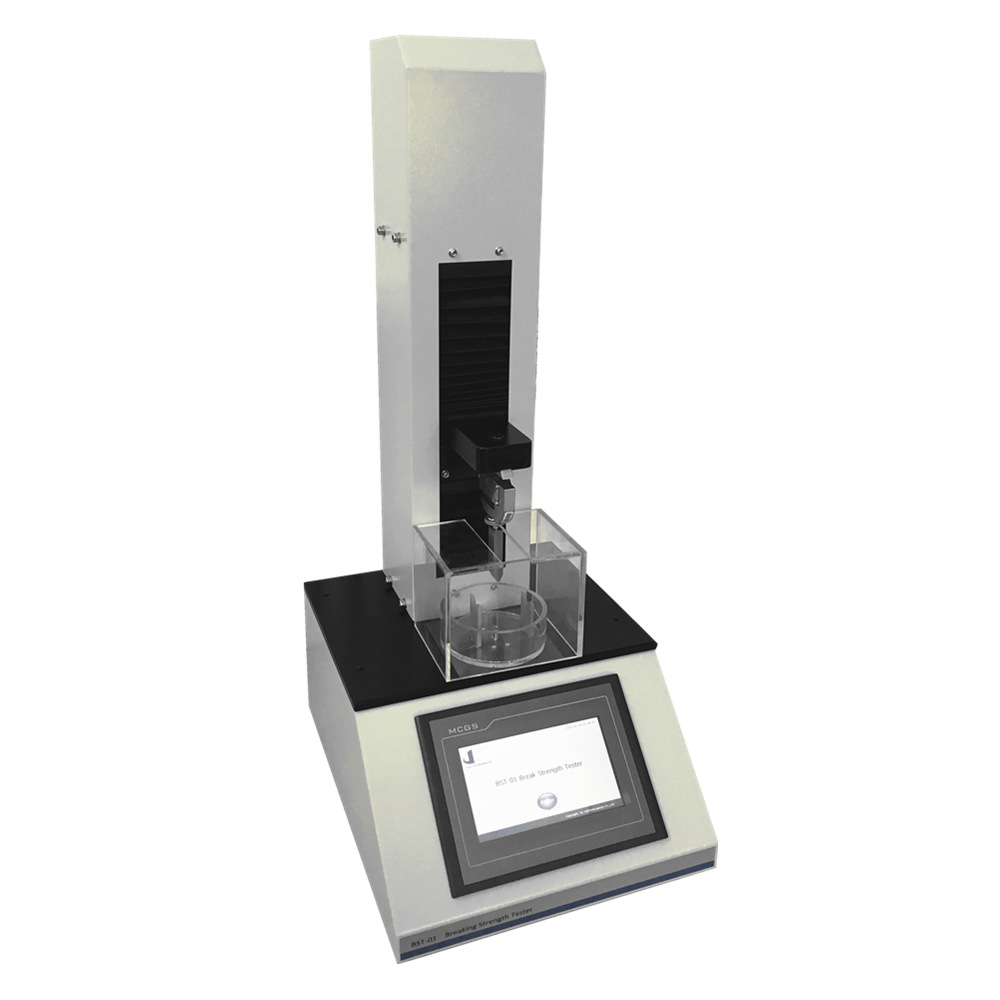

The Ampoule Break Force Tester is a critical tool designed to assess the force necessary to separate the ampoule stem from its body. Its primary objective is to ensure a clean break without leaving behind any sharp glass fragments that could pose risks to healthcare professionals and patients.

Breaking a glass ampoule is a routine task performed by medical practitioners, typically using bare hands or thin rubber gloves. However, if an ampoule requires excessive force to break or does not fracture cleanly, it can result in injury to the practitioner and potential contamination of the medication.

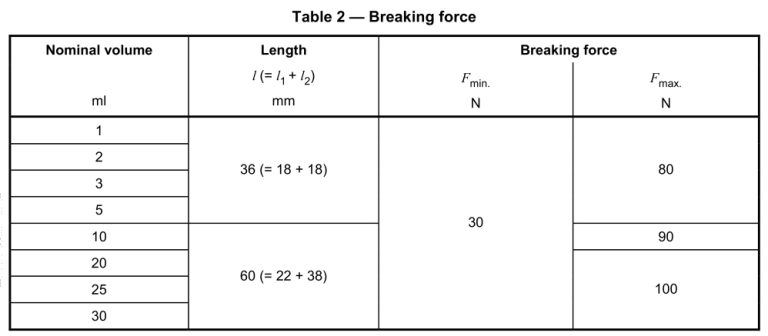

International standards, such as ISO 9187-1, GB/T 2673, specify acceptable breaking force thresholds for different sizes of ampoules.

The implications of inadequate ampoule break force are also significant. Not only does it pose risks to practitioner safety and medication purity, but it can also compromise patient care and treatment effectiveness.

By using the Ampoule Break Force Tester, which can be used to test various types of ampoules, such as straight-stem, funnel-type, and closed ampoules of ISO types B, C, and D with various break systems such as OPC (One Point Cut), CBR (Color Break Ring) and Score Ring, so healthcare facilities can mitigate these risks and ensure the quality and safety of medication administration.

How does BST-01 Ampoule Breaking Tester benefits pharmaceutical and medical sectors?

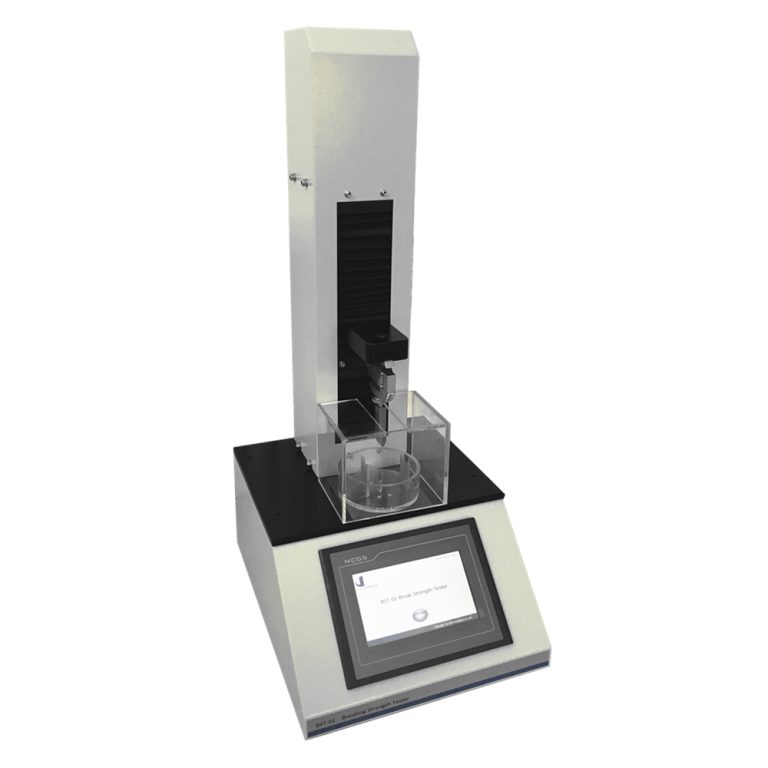

The BST-01 Ampoule Breaking Strength Tester is a cutting-edge equipment and its technical features and multifunctionality make it a standout choice for various testing needs.

Firstly, its constant rate of displacement ensures consistent and reliable testing results, essential for maintaining quality standards in pharmaceutical manufacturing. Additionally, industrial-level stability assures accuracy and precision, crucial for medical professionals relying on test outcomes for patient safety.

Furthermore, the PLC control and HMI touch screen features enhance the user experience by allowing for seamless operation and precise control over testing parameters. Combined with the stepper motor precision, this ensures that test results are not only accurate but also reproducible.

Functions of BST-01 Ampoule Breaking Tester

While its primary function is to assess ampoule breaking strength, its capabilities extend far beyond this. For instance, it can also be used for testing compression, cap opening, syringe gliding force, puncture resistance, and stopper penetration.

Technical Features

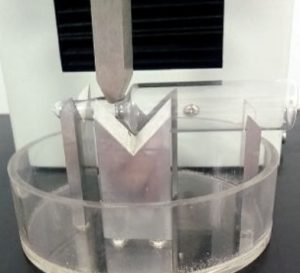

1. The BST-01 Ampoule Breaking Tester comes with different-sized test fixtures, ranging from 1ml to 30ml, to match different needs.

2. It also offers various fixtures for testing different materials in medical packaging.

2. It also offers various fixtures for testing different materials in medical packaging.

3. It has safety features like a limiting device and an automatic return function.

4.The test speed can be adjusted within 1~500mm(the common test method for ampoule breaking test is 10mm/min).

5. It includes a dot matrix micro printer for data output and longer-term keeping than a thermal printer output

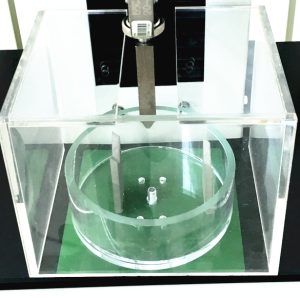

6. A protective cover for added convenience and safety.

7.Upon request, Cell Instruments can add different level of administration/authority to the test program to comply with 21 CFR Part 11.

8.Additionally, it can be connected via RS 232 and comes with optional professional software.

Ampoule Breaking Tester Specifications

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~500mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Standards

Q&A

Ampoules are preferred in medical settings due to their ability to preserve medication integrity by providing a sealed environment that prevents contamination and degradation. They also offer precise dosing and easy disposal, making them ideal for single-use applications in healthcare.

Testing ampoule breaking strength is essential to ensure the safety of healthcare professionals during medication administration. It helps prevent injuries caused by shattered glass and ensures that the ampoule breaks cleanly without leaving sharp fragments that could contaminate the medication or cause harm to the patient.

The proper breaking force/strength of an ampoule ensures that it ruptures cleanly and predictably. If the breaking force is too high, it may require excessive force to break, increasing the risk of injury to the healthcare professional. Conversely, if the breaking force is too low, the ampoule may break prematurely or unevenly, leading to spillage or contamination of the medication.

Testing ampoule breaking force/strength is an essential aspect of quality assurance in healthcare as it ensures that medications are administered safely and effectively. By verifying that ampoules break cleanly and predictably, healthcare facilities can minimize the risk of injuries to staff and patients, prevent medication contamination, and uphold the highest standards of patient care and safety.

Configuration

Main machine, ampoule holder, break punch, microprinter, loadcell

Software, customized punch, customized ampoule holder, loadcell, etc