Ampoule Breaking Force Test|Ampoule Quality Test

- Download Catalog

The key to quality testing of ampoules: breaking force test and application of ampoule breaking tester

In the pharmaceutical industry, ampoules are an important carrier for pharmaceutical packaging, and ampoule quality is directly related to the safety and effectiveness of pharmaceuticals. Therefore, it is particularly important to conduct strict quality testing of ampoules. Among them, the breaking force test is one of the key links to evaluate the quality of ampoules, and the ampoule breaking tester is an important tool to achieve this test.

Breaking Force Test

The breaking force test is designed to evaluate the mechanical properties of ampoules during the breaking process to ensure their safety and convenience in actual use. Through the breaking force test, we can understand the breaking force of the ampoule, the accuracy of the breaking position, and the fragments after breaking, so as to determine whether it meets the usage requirements.

Ampoule Breaking Tester

Ampoule breaking tester plays a key role in the breaking force test. This equipment uses a precise mechanical measurement system that can simulate the breaking process in actual use and accurately measure the breaking force of ampoules. At the same time, the ampoule breaking tester is also highly automated in data processing and movement, greatly improving testing efficiency and accuracy.

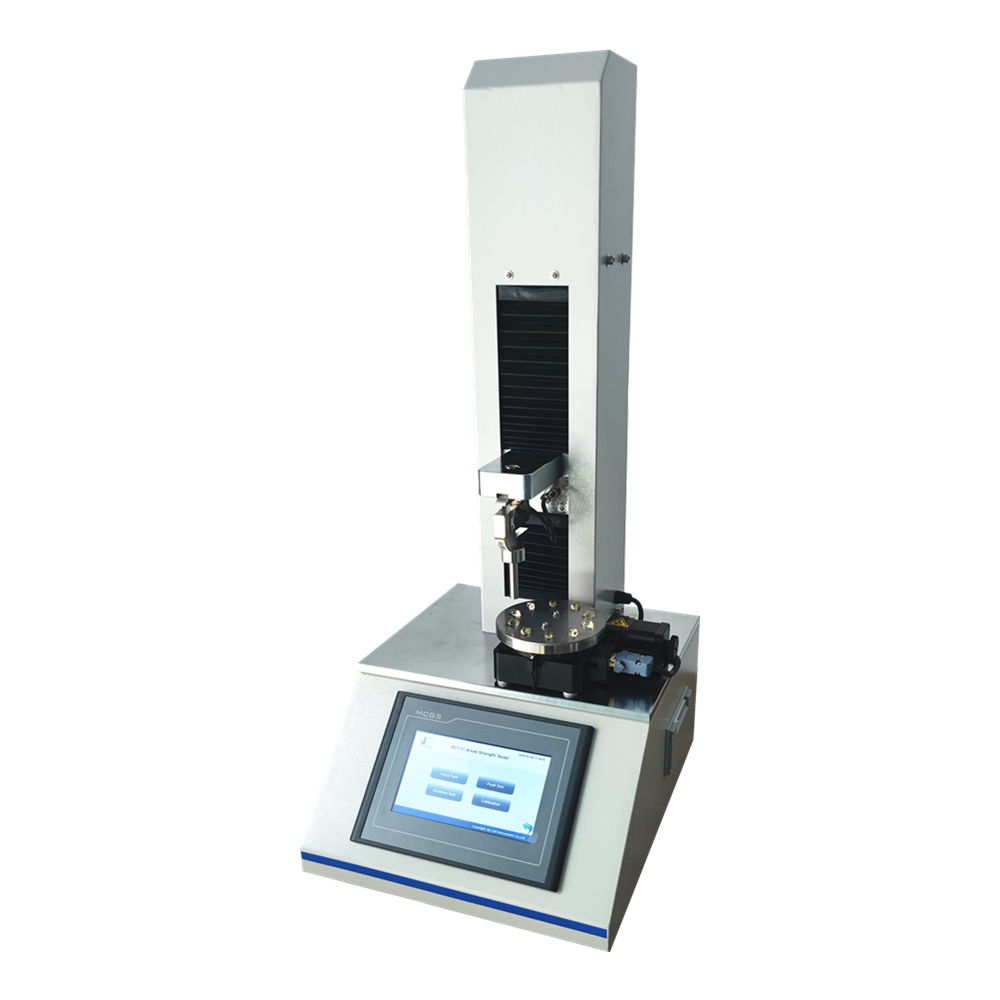

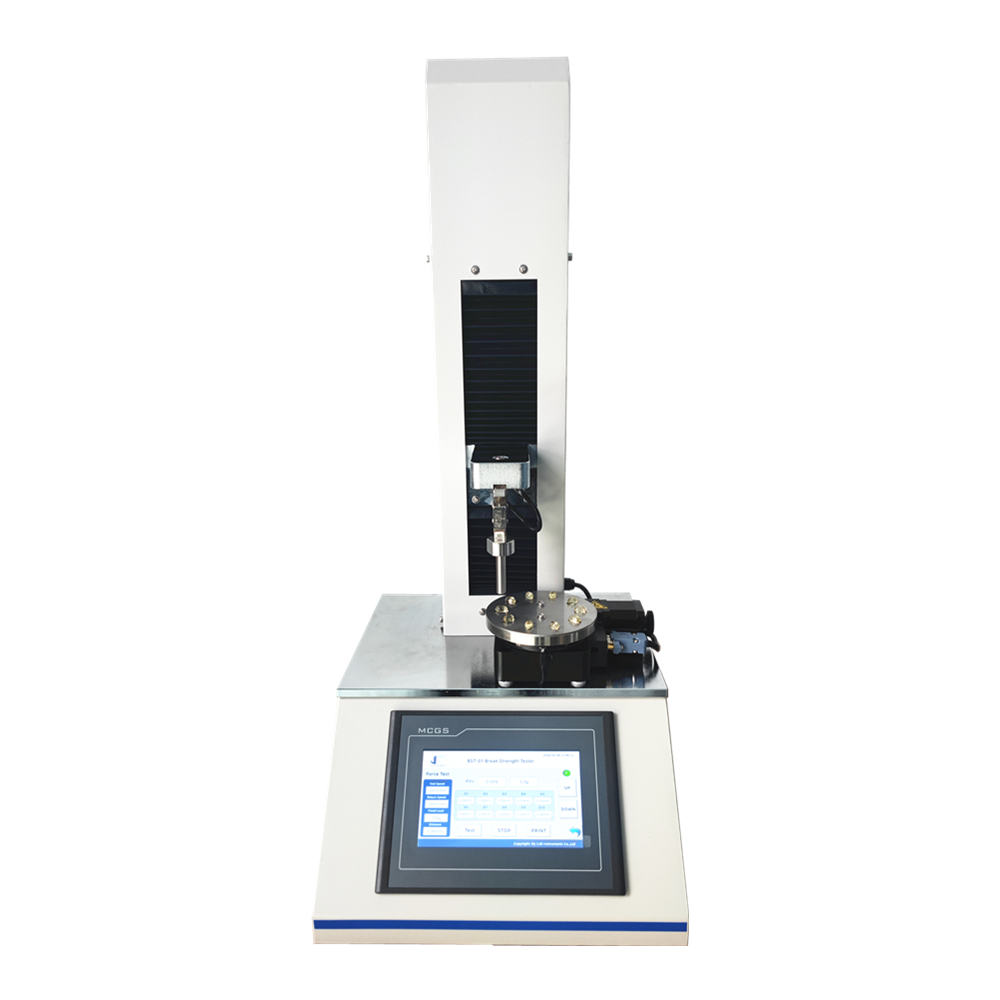

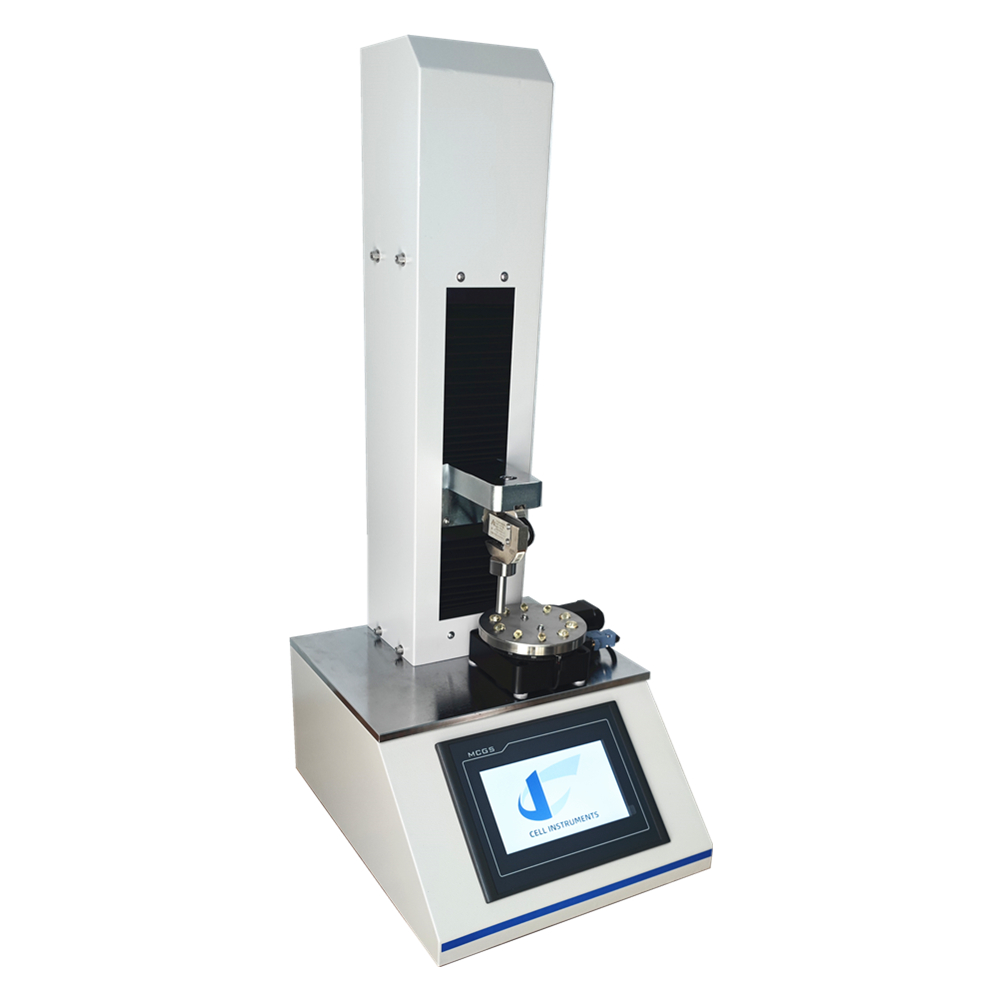

BST-01 Ampoule Breaking Tester is a type device in pharmaceutical industry.

Benefits and Technical Features

BST-01 Ampoule Breaking Tester is very useful and advanced, and it can be used in many ways in the pharmaceutical and medical fields. It has special features like a steady speed, strong stability, and PLC control to make sure tests are accurate. It also has a stepper motor that controls the speed very precisely. Plus, it’s very safe to use because it has a tube to collect broken samples and a cover to protect samples from jumping during testing.

1. Ampoule support fixture work for different volumes of 1ml, 2ml, 5ml, 10ml, and 20ml. This covers the most frequently used ampoule specifications.

2. Applications can be extended to other tests for medical devices and packaging materials.

3 . For safety, the tester has auto return function, overtravel, and overload protection.

4. Adjustable test speed to suit different requirements.

5. A dot matrix type microprinter is embedded to export a paper test slip for long-term reference.

6. A transparent protective cover is included for safety operation and observation of test process.

7. RS 232 Port and professional software are optional parts if user wants to have data export.

Specifications of BST-01 Ampoule Breaking Tester

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~500mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Standards

Multiple standards, including ISO 9187, GB 2637, and YBB00332002, regulate the evaluation of ampoule breaking strength

Q&A

N/A

Configuration

Main machine, ampoule holder, probe, microprinter, loadcell, protection cover, power cord

Software, customized probe, extra loadcell, COM Line, etc

How to Operate BST-01 Ampoule Breaking Tester

Medical Syringe Tester

MST-01 Medical Syringe Tester Download Catalog Please enable JavaScript in your browser to complete this form.NameEmail *Company *WhatsAppMessage *Name Send Message MST-01 Medical Syringe Tester is widely used A variety of assessments and measurements are carried out on individual manual syringes within the medical packaging sector to ensure the quality

Understanding Hydrolytic Resistance in Glass Containers for Pharmaceuticals

The pharmaceutical industry relies heavily on glass containers for the packaging and preservation of various products. These containers must possess certain qualities to ensure that they keep their contents safe and unchanged over time. One such quality is hydrolytic resistance – an essential characteristic that ensures that pharmaceuticals remain unaffected

Common Types of Gelatin Capsules

Gelatin capsules are widely used in the pharmaceutical and nutraceutical industries for encapsulating various drugs, supplements, and other substances. Here are some common types and variations: 1. Hard Gelatin Capsules (HGC): These widely used capsules undergo stringent hardness tests to ensure they maintain structural integrity. They are composed of gelatin,

Syringe Needle Penetration Test

NPT-01 Needle Puncture Tester Download Catalog Please enable JavaScript in your browser to complete this form.NameEmail *Company *WhatsAppMessage *Name Send Message What is Syringe Needle Penetration Test? Needle Penetration Test, also called needle puncture test, simulates the insertion of needle-like objects into materials such as rubber, closure, protective material, skin,

Vacutainer Draw Volume Test

RDVT-01 Vacutainer Draw Volume Tester Download Catalog Please enable JavaScript in your browser to complete this form.NameEmail *Company *WhatsAppMessage *Phone Send Message What factors affect the vacutainer drawing volume? When collecting blood samples using evacuated tubes, various factors can influence the volume of blood drawn. Understanding these factors is crucial

Ten Key Tests on intravenous bag Physical and Mechanical Performance

Intravenous bags, commonly referred to as IV bags or infusion bags, are indispensable in clinical settings, serving as vital containers for various medical fluids such as saline solutions and medications. Ensuring the quality and reliability of these bags is important to the safety and well-being of patients. This article delves